(Last updated on January 9th, 2023)

In this article, we will pit Fusion360 vs. Inventor for an ultimate comparison.

Fusion360 and Inventor are both owned by Autodesk and used for product development. These days there are many kinds of 3D CAD programs, typically specialized for a specific industry.

For example, Maya is specialized for 3D animation while Civil 3D is for civil and structural engineering purposes. Programs like Fusion360, Inventor, Solidworks, CATIA, etc. are geared toward modeling parts in 3D space and then putting those parts together into 3D assemblies.

These days, you can even simulate real-world conditions such as heat, drop-tests, and weight to see if the product will hold up.

Short Verdict

Let’s talk about which of these is better, generally speaking. I’ve done several of these articles comparing different CAD programs, and it often doesn’t make sense to say one is better than the other because they are usually for two different industries.

This comparison is one of the rare instances in which I can say the winner in this comparison is absolutely Inventor! Inventor is the more refined of the two and has more capabilities. When judging based on criteria, Inventor is just better and beefier and has more freedom.

You could argue that since Fusion360 is more straightforward and less expensive, it is better for some people. However, if you are serious about 3D modeling, the shortcomings of Fusion 360 just won’t be worth the time saved or the “user-friendliness.”

As far as “user-friendliness” is concerned, don’t be deceived! You may think that it is better to go the route of a program with a more natural learning curve, but you need to reconsider. Any of these apps for 3D modeling and developing a product have a steep learning curve. If you’re new to 3D modeling, you need to invest in real training via either a live class or an online course from a website like Udemy or Lynda.

Get up to 70% Off on Top Products!

Autodesk

See the latest Autodesk deals, discounts, promotions, and bundled packages. Save up to 70% on top products!

at autodesk.com

Inventor

Inventor offers industry-standard product design and engineering tools for 3D mechanical design, visualization, simulation, and documentation.

at autodesk.com

Fusion 360

Fusion 360 is a cloud-based CAD/CAM/CAE software for product design.

at autodesk.com

Basics of Inventor

CAD developers such as Autodesk are continually evolving with the industries they service. CAD professionals are needed in construction, manufacturing, clothing design, remodeling, film animation, architecture, engineering, etc. Inventor was developed to parallel the popular software Solidworks owned by Dassault Systems. Solidworks broke the mold of what was considered possible in 3D design, so Autodesk was quick to produce a competitor. What makes Inventor so desirable versus other 3D software?

1) Specialized time-saving tools for modeling parts such as a library of standard screws and bolts (as well as the corresponding holes).

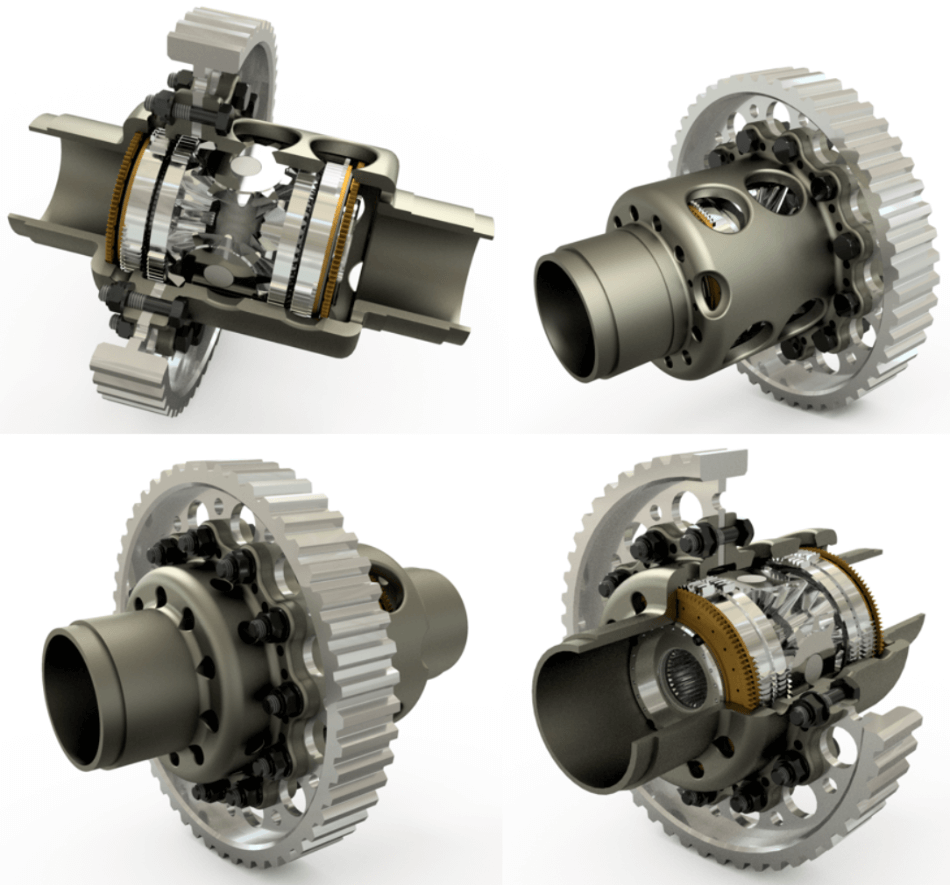

2) User-friendly assembly tools, enabling you to quickly drag and snap parts together while assigning them behaviors that mimic real-world operation. (For example, gears can be fit together in such a way that spinning one gear causes the rest to rotate appropriately)

3) Simulation tools used to test stresses upon the product so the parts can be refined. A stress simulation can reveal how much of a component is unnecessary and can suggest which sections of the component can be cut away to lighten the device.

Basics of Fusion 360

Fusion 360 performs almost all of the same functions as Inventor, but the primary difference is that Fusion360 is a cloud-based application. A team can easily collaborate using Fusion360. For example, different team members might be working on different parts of the product and linking those parts together in the general assembly.

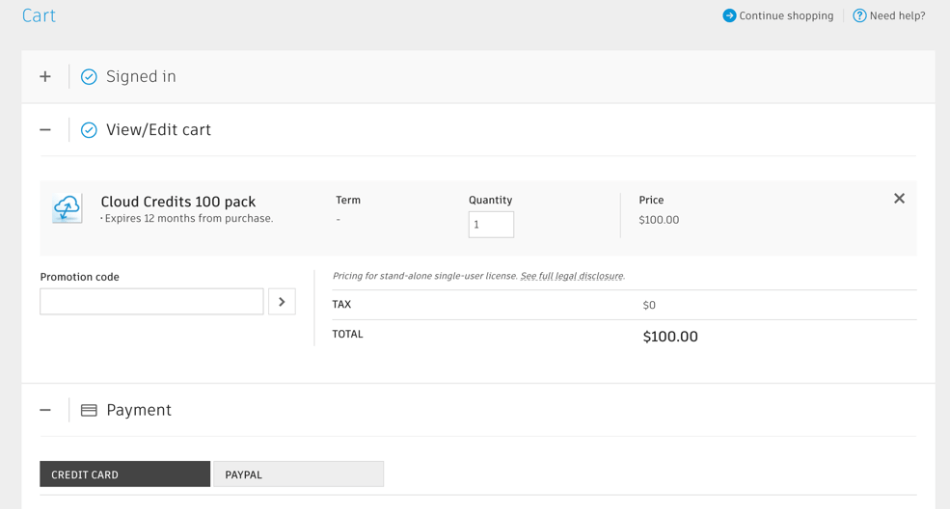

The changes and various iterations of the modeling process are all recorded in the project’s history on the cloud. You can also utilize cloud-based processing tools for more complex functions such as rendering or stress simulations. Whenever you use cloud-based processing tools, you’ll need to pay extra Cloud Credits.

Alternatively, you can use your local hardware (i.e., your computer) to run these tedious processes, but this will take much longer and tie up your computer.

Inventor Vs Fusion 360: Head-to-Head Comparison

| Criterion | Inventor | Fusion360 | Notes |

| Price | N/A | Winner | |

| User Experience | Tie | Tie | Both are Autodesk products. |

| Learning Curve | Tie | Tie | Try self-paced learning |

| Capabilities | Winner | N/A | |

| Parts Library | Winner | N/A | |

| Assemblies | Winner | N/A | |

| Materials | Winner | N/A | |

| Simulation | Winner | N/A | |

| CAM | Winner | N/A |

In-Depth Considerations

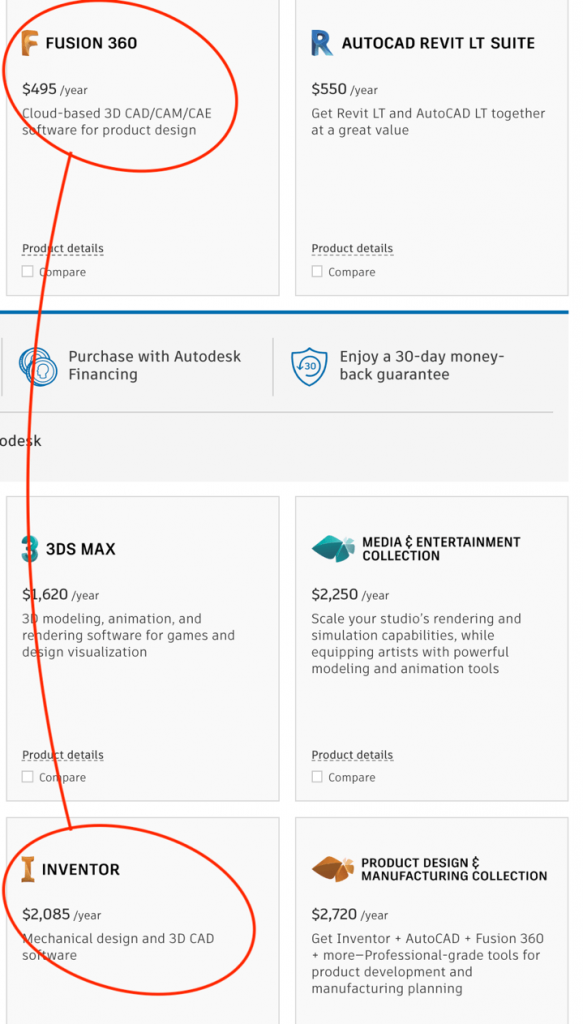

1. Price

| Product | Regular Price | Discounted Price |

| Inventor | $2,085/year | Check here |

| Fusion 360 | $495/year | Check here |

| Autodesk Deals & Packages | varies | Check here |

Winner: Fusion 360 (but beware of Cloud Credits!)

A few years ago, Autodesk made the transition from selling perpetual licenses of its products to selling subscription-based service.

If you are paying your annual fee, you gain access to the latest and greatest version of whichever app you are using. Alternatively, you can pay monthly or Tri-annually (Is that the right term? Tri-annually? You pay every three years.)

Free trial: Yes for both programs

Student Version: both applications are free for students and educators

Fusion 360 is available either: 1) Monthly for $60 2) Annually for $495 3) Tri-annually for $1,335

Inventor is available either: 1) Monthly for $260 2) Annually for $2085 3) Tri-annually for $5,630

2. User Experience

Winner: Tie

After considering many of these applications and the importance of User Interface (or UI), I am starting to realize that you have to put time and energy into learning any CAD software. Both Fusion360 and Inventor are powerful tools with a lot of functions and options (and I mean a lot of functions and options).

I like the way Fusion360 looks and feels, but ultimately both Inventor and Fusion360 are very well designed and strive to push the envelope of the cutting edge.

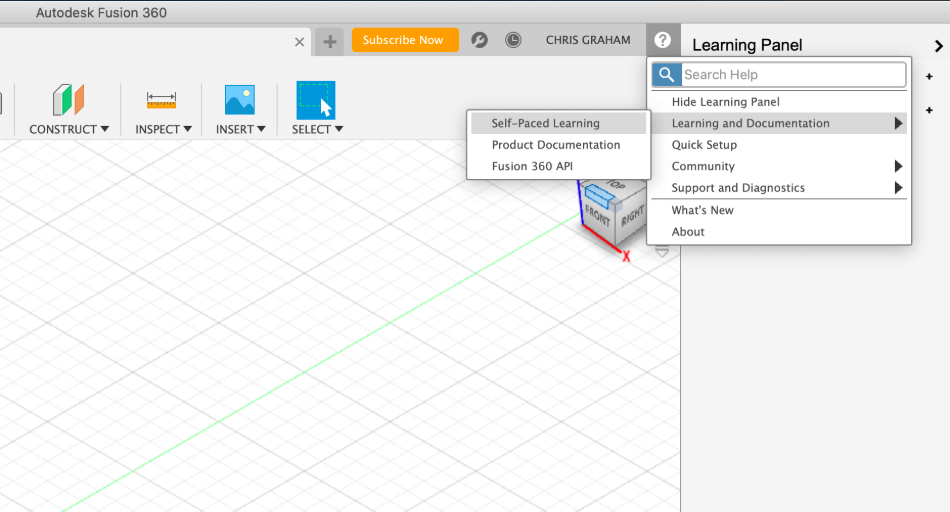

3. Learning Curve

Winner: Tie

I am tempted to say that Fusion360 has a more natural learning curve, but I need to call this one a tie. The reason I say this is that no matter how simple these programs appear to be, you will need to put some effort into learning the ropes, or you will never be proficient.

I encourage people not to fall into the trap of assuming that a smoother learning curve is desirable. If you are going to be serious about producing products using CAD, then don’t let a steep learning curve intimidate you at all. Think of it as a rite of passage.

No matter how complex the program’s capabilities, you need to master the essential core skills and then specialize in the peripheral skills that might support your purposes. It doesn’t matter how well the software is designed for user-friendliness; you need to put the effort and time in to learn the skills you need.

Download the free trial of either program and get started on the Self-Paced Learning (Fusion360 UI shown below)

4. Capabilities

Winner: Inventor

Fusion360 is neck-and-neck in many areas with Inventor, when all things are considered. However, Inventor tends to be a little more flexible and has fewer limitations than Fusion 360.

One of the most significant areas of distinction is Inventor’s greater customizability. Everything is more customizable in Inventor. Larger companies tend to prefer more customizability than smaller companies or hobbyists.

5. Parts Library

Winner: Inventor

One of the most significant criticisms I’ve seen regarding Fusion360 is possibly the most crucial. I’m not sure if things have changed recently, but according to my research, Fusion360’s parts library is lacking significantly versus that of Inventor.

If you are going to produce a product, you need to utilize many standard parts such as wiring, springs, screws, bolts, screw holes, etc. Without the ability to quickly pop in the necessary standard connectors, your idea will have trouble becoming a reality.

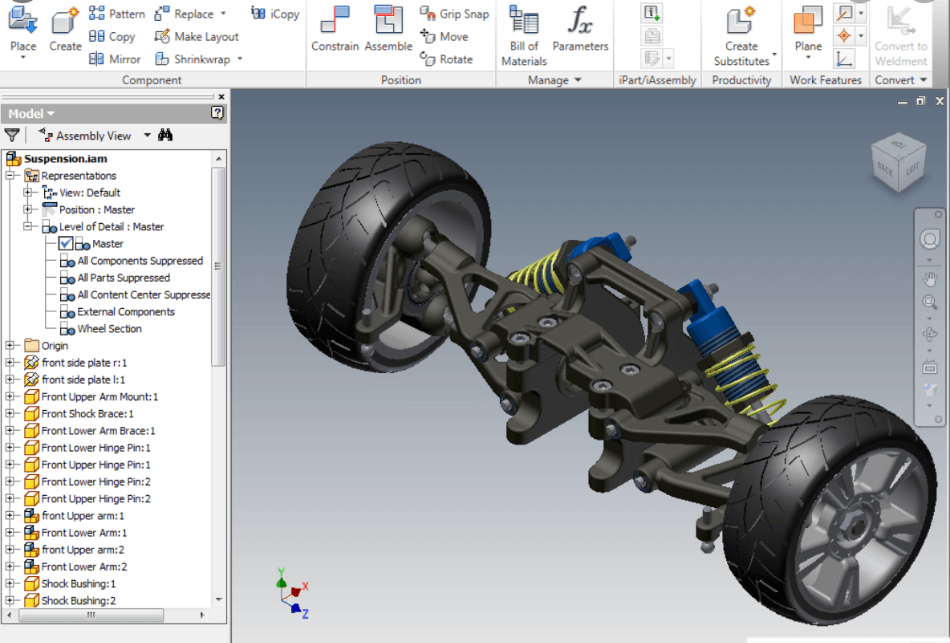

6. Assembly

Winner: Inventor

An assembly is when you take all the little parts you’ve modeled for a particular product and put them all together in their proper place. Inventor and Fusion360 both produce great assemblies, complete with easily programable constraints and relationships.

A “constraint” would be, for example, making two faces of a part parallel with one another, no matter where they are moved. It is satisfying to watch all the parts click together on, say, a dirt bike, and then see the front wheel turn as you move the handlebars.

(Inventor Assembly shown below)

7. Materials

Winner: Inventor

You’ll notice a pattern as I continue. Inventor and Fusion360 can both perform the same functions and are very similar to one another in many ways. It’s just that Inventor’s more excellent capability is causing me to decide in favor of Inventor in these categories.

Applying specific materials to your models is critical for developing products according to industry standards. Many of the functions that make these programs useful depend upon how close to real-life the materials are. The entire purpose of these programs starts to break down when comparability to reality breaks down.

Without a perfect set of standard materials and parts consistent with your manufacturer’s specs, you will be left unable to utilize half of what you are paying for with these programs.

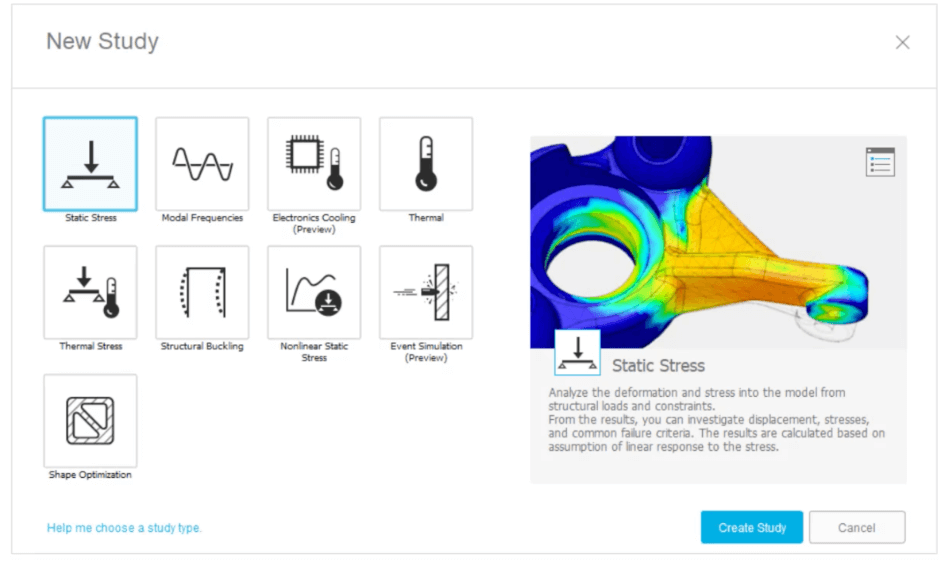

8. Simulation

Winner: Inventor

Again, when it comes to which of the two is better, Inventor and Fusion360 can both run simulations, but Inventor tends to have more customizability. Yet, this verdict isn’t by a large margin.

Fusion360 is very impressive in how compact it appears to be at first glance, and upon further inspection, you find it is like a multi-tool with yet another little hidden gadget. The simulator in Fusion360 and Inventor can help you spot where the most likely points of failure are in a modeled part and how to correct those weaknesses as necessary.

You can apply specific forces to specific areas, and simulate drop-tests, etc.

9. CAM

Winner: Inventor

CAM tools in applications like Fusion 360 and Inventor give you a simulated preview of how industry-standard CAM tools such as water jets, laser cutters, and lathe machines will fabricate your part. This simulation can help preemptively spot issues in fabrication, saving costly mistakes.

Cloud Credits – Fusion360’s Hidden Cost!

It’s important to point out the potential hidden cost of Fusion360. Rendering, CAM simulation, stress simulations, intuitive design (which is apparently where the software AI figures out how to design the part for you…wacky stuff!), and several other services can be done on Autodesk’s Cloud servers.

The advantage of these servers is the processing power that it affords you. Although it costs $25 to run a complex stress simulation, if that simulation would tie up your computer for 15+ hours, it is well worth the cost.

The Advantages of Fusion360

I’ve been pretty hard on Fusion360, so I feel the need to accentuate the advantages of Fusion360. My verdicts are based strictly on; “which of the two is more powerful and more capable?” So, I lean toward Inventor, but as I have continued to study up on Fusion360, I am fascinated by this product.

It is less expensive than Inventor by a wide margin, yet it can almost do everything that Inventor can do. Yes, there are additional costs for cloud-based services of Fusion360, but many of them can be done locally on your hardware at no extra cost.

Fusion360 can also run effectively on a less powerful computer because it is a cloud-based platform. Fusion360 UI has a clean, tight feel to it, and it reminds me of Sketchup. When Sketchup was first developed, the idea was to produce an intuitive 3D modeling program with simplified tools that were easier to use.

The result was a stripped-down program that was missing a lot of functionality to gain the apparent advantage of being easy to use. I have been pleasantly surprised to find that Fusion360 has a look and feel of being very easy to use, while still having enough functionality to make it practical for real-world applications.

Fusion360 is very impressive to me, and I have been considering purchasing a subscription for myself.

I recently spoke to a customer service rep for Fusion 360. I was pleasantly astounded that after my 30-day trial is complete, I am welcome to continue using it until I’m ready to purchase a subscription for commercial purposes.

How do these Programs Work?

If you don’t understand how these programs work, then read this section. Inventor and Fusion360 are both intended for professionals and hobbyists who are developing products for real-world production. If you’re just looking to dabble in 3D modeling, there are other, less expensive options.

Blender is a great program that is free and developed by volunteer programmers. You can donate to their cause, but the software is free. However, when you need a powerful program to develop a product from scratch and produce it in the real world, Inventor or Fusion360 is head and shoulders over a freeware such as Blender.

Let’s say you wanted to design a waterproof electric razor. It needs to be designed artistically and practically. It needs to be drawn and engineered. From an artistic perspective, how will it stand out? What color will it be? What will the brand logo look like, and what will the name of this product be?

All these visual decisions add appeal to a product that can make or break it. However, just being aesthetically pleasing isn’t going to be good enough if it doesn’t work as advertised. You need to decide how big it will be and where all the parts will go inside of this sleek, handheld device. A considerable amount of this work needs to be done before you even make your first mouse-click in your CAD program.

Building the shapes in a 3D program requires specific parameters. You can’t just start throwing parts together without knowing how the engineered design will fit together and function.

As things become more clarified, you can start putting some well-thought-out ideas into your CAD program. With a lot of work, you will eventually have a complete little product that is ready for testing. So here is where the difference between Inventor and Fusion360 starts to become relevant.

Remember how we said we wanted to produce a waterproof electric razor? To my knowledge, Fusion360 can’t do fluid tests, and for this product to be waterproof, you’ll need to design the battery and motor housing in a way that will function. Accurate simulations can help avoid producing prototype after prototype to see which one effectively protects these parts from water.

After running several simulations and tweaking your model and parts, you’ve finally got a finished, waterproof electric razor from scratch! From here, you will need to figure out how each part will be fabricated, what it is made of, and how much these parts cost to produce. Since you can simulate CAM, you can get a reasonable estimate of production time (and since time=money) how much it will cost.

How about that!? You’ve just designed a waterproof electric razor from scratch, and it only took you a month or so.

(Left; Fusion 360 rendering – Right; Inventor rendering)

Summary

Fusion360 has my respect, don’t get me wrong, but at the end of the day, Inventor takes the cake as a beefier, more flexible, and more capable program. Autodesk sinks a lot of money into making Inventor one of its flagship programs, and it meets the need of the top industries in the world.

Fusion360 is no slacker, however, and while it may look overly simple, you will be shocked, just as I was, at how much it can do and how well it can keep up with the heaviest hitters in the CAD/CAM world.

I’m even to the point where I want to try Fusion360 out and do some freelance modeling work using this platform. Fusion360 is excellent for cloud-based collaboration and file-storage; it feels intuitive and straightforward, and perhaps deserves more market respect than it currently has.

I’ve read some criticisms about Fusion360’s parts library and how this shortcoming is probably the biggest problem that it has. Maybe in the future, this problem will be solved (if they haven’t solved it already!), and Fusion360 will take more of a commanding lead.

Chris Graham is an experienced Computer-Aided Design (CAD) draftsman and a writer. He has extensive knowledge of almost all the top CAD software available on the market these days. From simple tasks to developing a professional CAD drawing, he can do everything.

He also has a Bachelor of Architecture (B.Arch.) (Landscape Architecture & Civil Engineering) degree from the Louisiana State University School of Architecture and Design. He has worked at the Corporate Green Landscape Management where his duties included landscape design, irrigation design, landscape installation, CAD drafting.