(Last updated on January 9th, 2023)

Inventor or Solidworks, which software is a better choice in 2023? Or is there a clear winner between the two?

Read this ultimate Inventor vs. Solidworks comparison to get all the answers.

In this article, I am going to compare Solidworks by Dassault System versus Inventor by Autodesk. These two apps are incredibly similar, and it is no secret that they are the key competitors in the 3D CAD/CAM product design arena. Most of the things in your house were probably designed by someone using CAD software.

I would be willing to bet money that at least one thing in your home was designed using Solidworks or Inventor. I can only give you my opinion, so here it is; Neither is better than the other. There you go! I said it! Wanna fight about it? Come on, put up your fists, let’s go! I’ll repeat it, whether you like it or not; Neither Solidworks nor Inventor is better than the other.

When I first started writing this article, I thought to myself, “Oh no! Please don’t make me do this! Solidworks vs. Inventor?” I’ve written several articles comparing different CAD apps, and so far, it has been easy to distinguish one from another. This article, pitting Solidworks against Inventor, seemed like a challenge, and I wasn’t sure how to do it.

I thought, “How am I going to prove whether Solidworks is better than Inventor, or vice versa?” However, as I thought about it, I realized the answer is straightforward. I can’t prove it either way. Every honest comparison I’ve read from others has always touted the same idea; they are both very similar, and it comes down to personal preference.

These two are fantastic competitors, and they push one another to become better. As far as I’m concerned, it is suitable for this competition to continue for years to come.

Short Verdict

I stick to my guns; neither of these apps is better than the other, so you are going to have to decide for yourself which is right for you. You can download a 30-day free trial of both of them and test them out for yourself.

That being said, I’m going to do my diligence to show you how they stack up head-to-head. The differences are minor, and I’ll point some of them out. But, at the end of the day, you’ll have to decide yourself which one you prefer just because you like the name better.

“Ooo Solidworks…sounds so cool…but Dassault is a weird word, I don’t know how I feel about that. On the other hand, Inventor is a very plain name…but Autodesk rolls off the tongue nicely, doesn’t it? Hmmm…tough choice…”

Get up to 70% Off on Top Products!

Autodesk

See the latest Autodesk deals, discounts, promotions, and bundled packages. Save up to 70% on top products!

at autodesk.com

Inventor

Inventor offers industry-standard product design and engineering tools for 3D mechanical design, visualization, simulation, and documentation.

at autodesk.com

BIM 360

BIM 360 is a professional-grade construction management software that connects, organizes, and optimizes projects from design to finish.

at autodesk.com

A Brief History of Solidworks and Inventor

Solidworks was initially a product of Solidworks Corporation, developed in 1995. Dassault System acquired Solidworks in 1997 for $310 million in stocks. Autodesk started to realize how popular Solidworks was becoming, so they developed the Inventor as a direct competitor. The rest, as they say, is history.

Comparison At a Glance

After you get a conceptual idea, you need to refine it until you have a good idea of how all your parts would fit together. Then, when you have measurements and conceptual drawings, you can model the individual pieces in Solidworks or Inventor. Having done that, you put them together in an assembly.

You then test them out using the simulation tools. After testing, you can refine the design a little. Then when you’re satisfied with the design, you can simulate how a CAM device would produce the parts.

Provided you have access to manufacturing capability, you can send this data over to a factory and have your invention prototyped! Having scrutinized the prototype, you can probably find a few more areas of improvement, so just modify the 3D model one more time. You’ve just created a project from scratch.

Let’s look at a few criteria to judge these programs and see how they stack up:

| Criterion | Solidworks | Inventor | Notes |

| Price | Tie | Tie | You have to crunch some numbers on this one, but it is a tie |

| UI | Tie | Tie | They are very similar |

| Compatability | NA | Winner | Compatible with other members of the Autodesk family |

| Rendering | Tie | Tie | The best renderings require plugins to help. |

| Materials | Tie | Tie | |

| Simulation | Tie | Tie | |

| Assemblies | Tie | Tie | |

| Learning Curve | Tie | Tie | Solidworks tends to have a more “viral” presence, but that doesn’t mean it is effective to learn from Youtube. Signing up for a real class carries a lot of weight. |

(You know, the word “Tie” looks so weird when you see it so many times…)

In-Depth considerations

1. Price

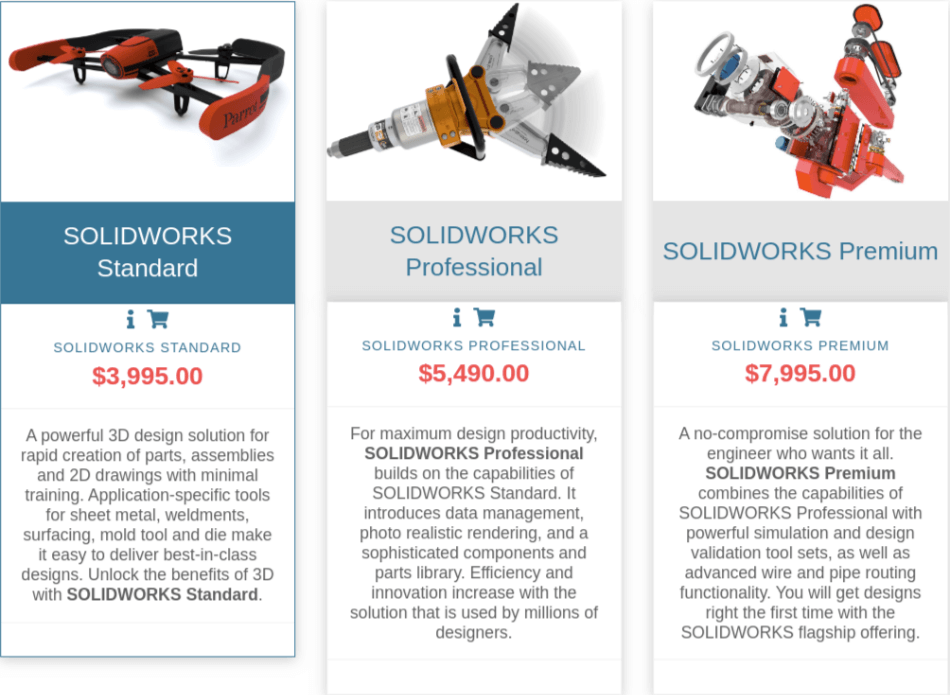

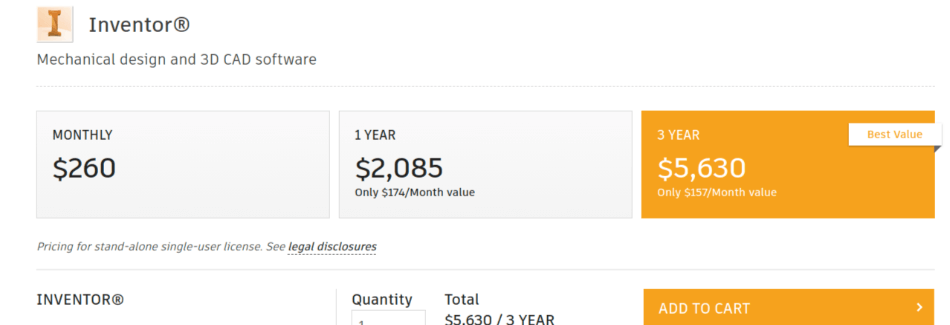

| Product | Regular Price | Discounted Price |

| Inventor | $2,085/year | Check here |

| Solidworks | $3995 license + $1295/year | No Discount |

| Autodesk Deals & Packages | varies | Check here |

Winner: Tie

Yes, believe it or not, I’m calling this one a tie. I’m considering the use of these programs over the long-term, let’s say over 6 years. Autodesk used to offer their software with perpetual licenses, but these days they charge only a subscription fee. Either monthly, annually, or every three years.

Cost of Inventor over 6 years = $5630/3-years x 2 = $11,260

Cost of Solidworks over 6 years = $8000 for premium license + Annual Subscription ($1600) x 5* = $16,000

*This is assuming you don’t have to pay the subscription fee for the first year.

Why am I calling it a tie? Because I predict that in the next few years, Dassault Systems will offer the same pricing style as Autodesk with similar pricing. If I stretch this comparison out by another 6 years, the two numbers become much closer together:

Solidworks after 12 years: $25,600

Inventor after 12 years: $22,520

You might still say, “But Solidworks is still more expensive!” Yes, but not by much, and you don’t know if the pricing would change at some point. If we take it forward a few more years, Inventor will start to be the more expensive option.

In 20 years, the way we do CAD may be entirely revolutionized by brain-nanites, and we won’t even need Solidworks or Inventor…you never know…

Other Price Considerations:

- Student Edition: Solidworks offers a student/educator license for $150/year. Inventor is free for students and educators.

- Maintenance Subscription: So, to clarify, the maintenance subscription is a fee you pay to Dassault Systems annually that automatically upgrades you to that year’s latest version of Solidworks. You don’t technically have to keep upgrading, but if you wanted to upgrade later down the road… well… you’d have to pay full price for that new license, as far as I know. So I consider it a necessary part of the package for long-term users and professionals.

2. UI

Winner: Tie

The Inventor and Solidworks UIs are very similar; both offer contextual right-click menus and have very comparable tools and commands. There are options menus within options menus within options menus (it’s like the movie Inception with Leonardo DiCaprio). You can model anything imaginable using either application.

If I had the time and resources, I would host a head-to-head competition between several experienced Solidworks users and several Inventor users. We could pit them against one another to see if either software is clearly faster and easier to use than the other.

Barring some kind of official competition like this, both UIs and toolsets are basically the same, or so similar that you can’t really distinguish between the two. As the years go by, you might have one company out-do the other, but soon after that, the other would add that functionality to keep up. So there’s just no practical reason to try to distinguish between the two in this category.

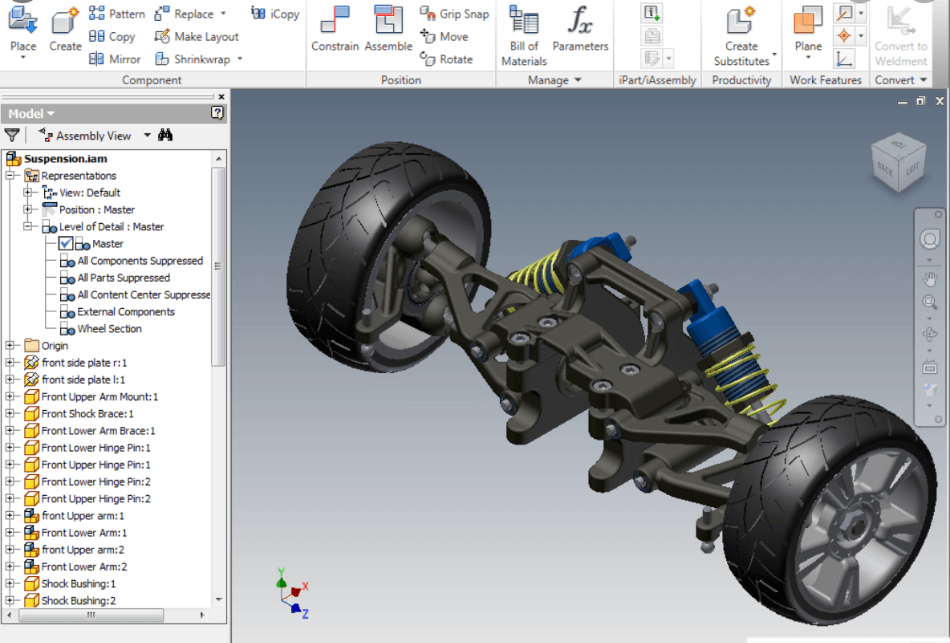

(At first glance, the UIs are pretty similar.)

3. Compatibility

Winner: Inventor

I would say this one goes to Inventor, because Autodesk has such an extensive offering as far as CAD apps, and they tend to play well together. Apparently, Inventor can export to Revit, but I’m not sure why you would need to do so. Maybe someone can comment down below as to why an Inventor file would need to be exported to Revit.

Inventor can export a DWG file, so you can model parts and then open them in AutoCAD. Also, Inventor can import DWGs, but only 2D drawings. So overall, there is more compatibility between the different Autodesk platforms. Solidworks, I find, tend to be more stand-alone.

4. Rendering

Winner: Tie

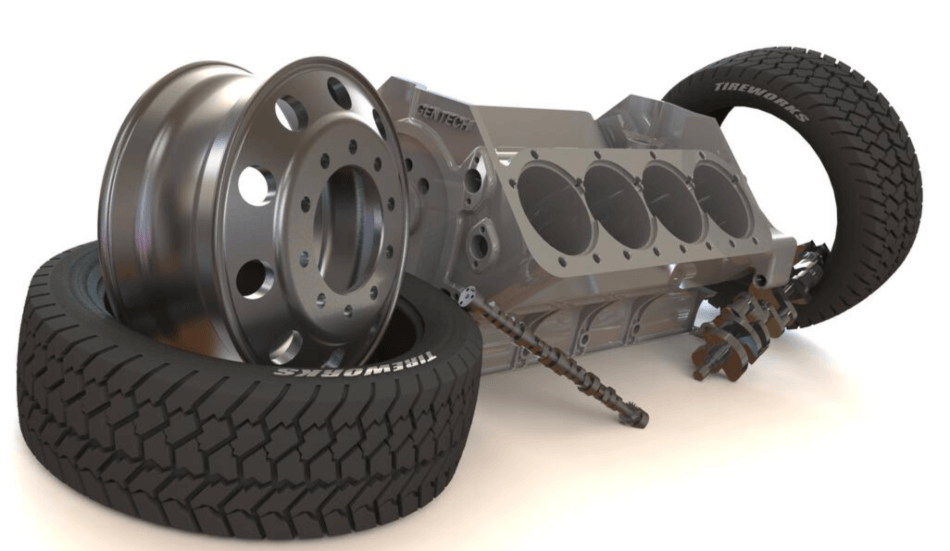

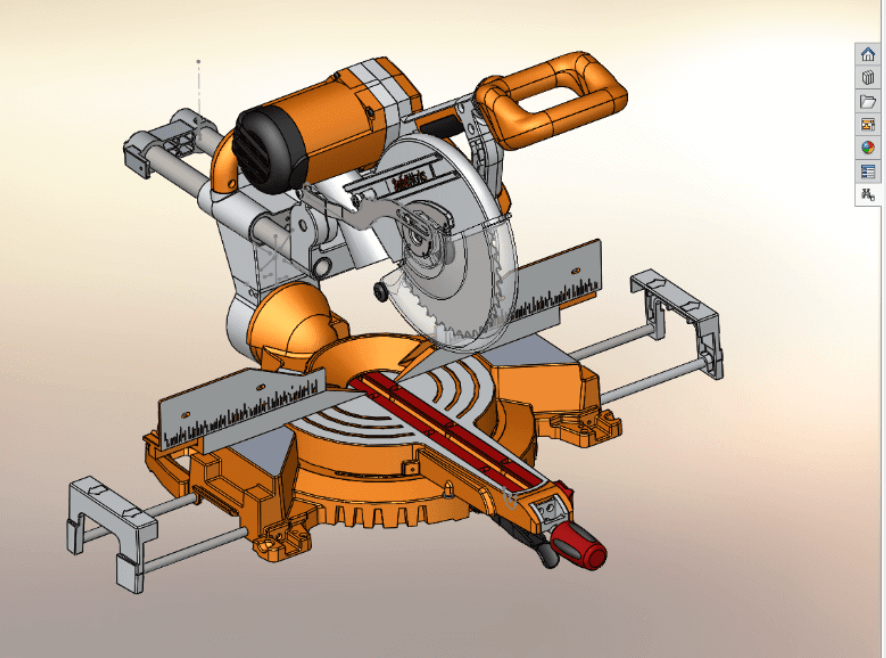

So this category is also a tie, as far as I’m concerned. I find the same rule applies in this category as the one above. Unless we get a bunch of competitors together to prove empirically that Solidworks can produce better renderings than Inventor (or vice versa), then this is a tie. Both applications can create photorealistic renderings of a very complex nature.

There’s an extensive library of textures and materials that do an outstanding job of fooling the average person. I actually work for a construction company doing a lot of interior remodeling for residences. Many different vendors sell products to us, and they all have their own literature and catalogs.

Those magazines and catalogs feature their products in arty-looking scenes and buildings. I’m starting to realize that most of the time, those pictures are photorealistic 3D renderings. It makes sense, after all. Why spend thousands of dollars building sets and taking pictures, when you can just make a 3D photorealistic picture?

(Which of the images below is rendered in Solidworks and which is rendered in Inventor?)

5. Materials

Winner: Tie

In the good old days, I thought the coolest thing about a 3D CAD program was making a little teapot and then selecting “porcelain” from the materials library. Then I would click the “render” button and wait…for a while…until it was finally finished! The little 3D shapes were suddenly this gorgeous and real-looking shiny teapot floating in a gray 3D space.

I thought, “Wow! I just made this fake 3D shape look real!”

These days, 3D has gotten a liiiiitle more sophisticated. So now, instead of just making it look like a porcelain teapot, I can actually make it think like a porcelain teapot. That sounds weird, but let me explain. Solidworks and Inventor can be used to apply the physical properties of a material to a 3D shape.

I’m talking about thermal conductivity, tensile strength, fracturing, shearing, melting point, etc. Solidworks and Inventor both have extensive material libraries, and both can create customized materials.

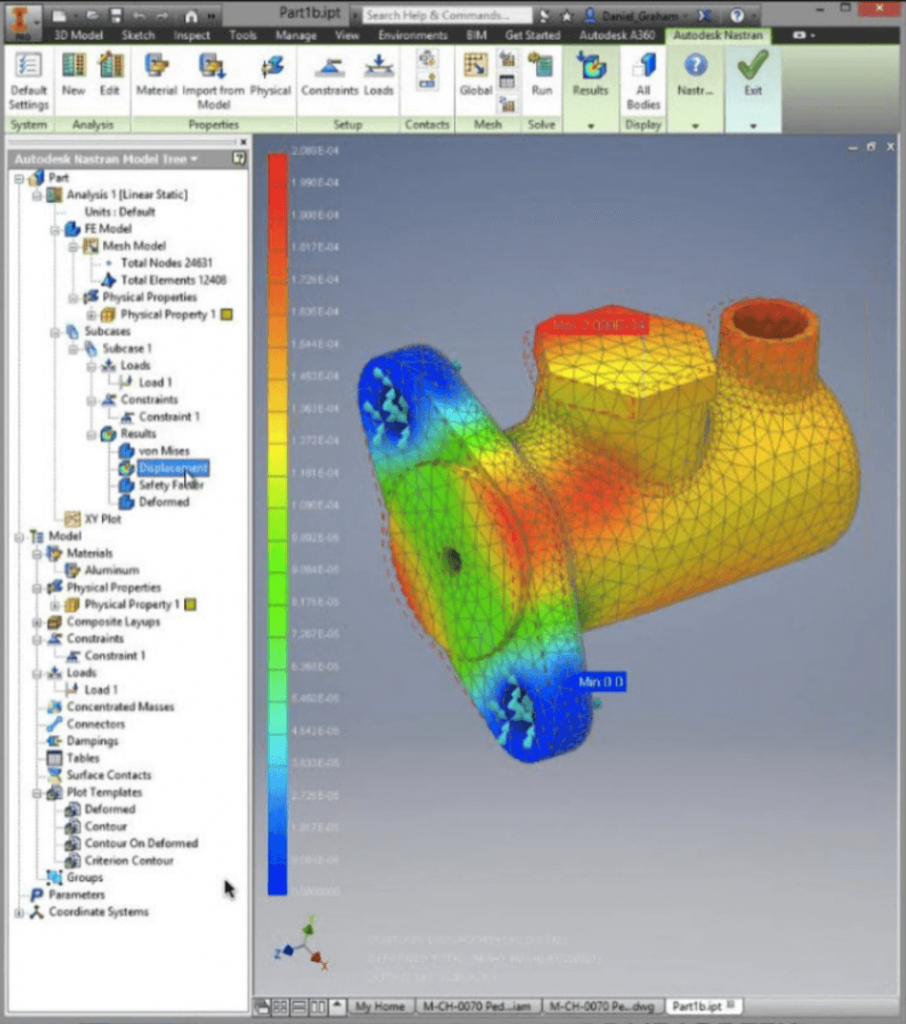

6. Simulation

Winner: Tie

Simulations include stress tests, fall tests, impact tests, etc. It is impressive, really, what CAD can do these days. When you are running these simulations, you can run stress tests to see how well a part will hold up. If it is tougher than it needs to be, then maybe it is heavier than it needs to be.

There are some great tools in Solidworks and Inventor that can be used to trim away unnecessary segments of a part. Lowering weight and material costs is critical to manufacturers. So if the CAD program can figure these things out without needing to run real-world trials in a testing lab, then the development costs are drastically decreased.

Overall, both Solidworks and Inventor are neck-and-neck in their ability to simulate forces and stresses.

7. Assemblies

Winner: Tie

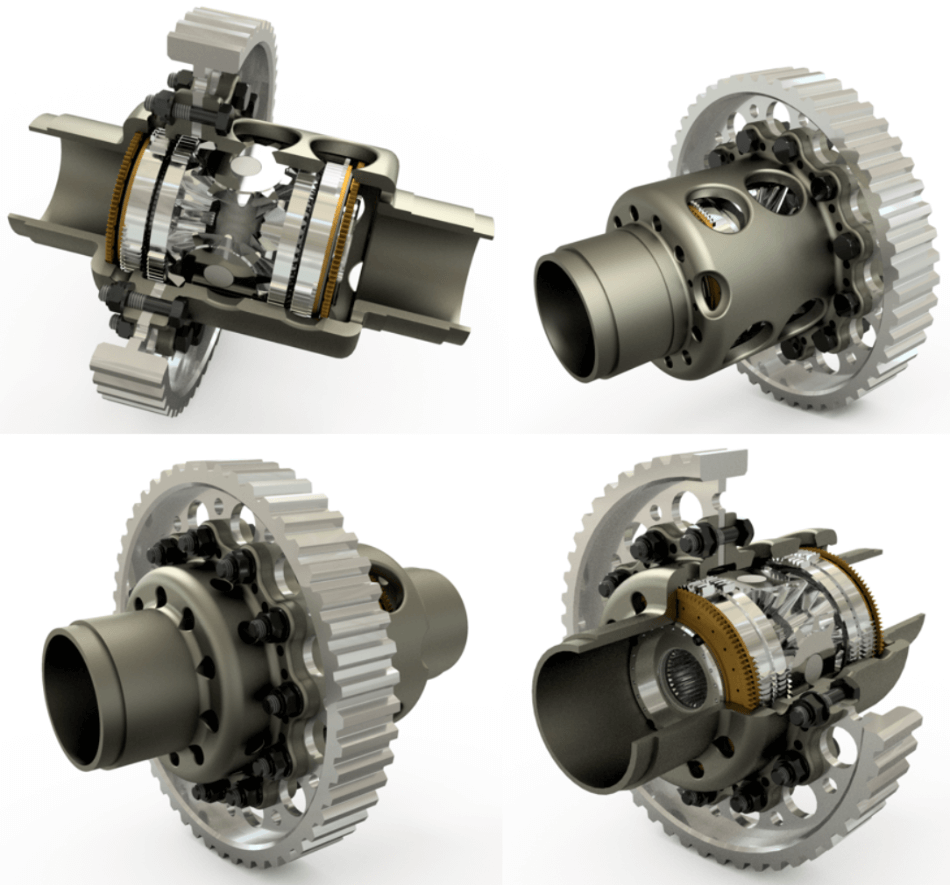

Solidworks and Inventor can put thousands of parts together into a single assembly. To me, the most amazing thing about doing assemblies in these apps is the ability to apply “relationships” and “constraints” to the parts. You can quickly snap the pieces together, piece by piece, and tell the parts how to behave with one another.

You can have a gear fit precisely into another gear, and then you can spin one gear with another. Necessarily, you can model an entire engine and watch it run exactly as it would in real life. As far as I can tell, both Inventor and Solidworks are mostly on par with one another when it comes to assemblies. I’m sure there are some differences, and some people may prefer one over the other.

Still, to me, they are mostly too similar to be able to say one is better than the other.

(Which assembly was done in Solidworks and which in Inventor?)

8. Learning Curve

Winner: Tie

I’ve seen these apps in action, and as far as I can tell, they are both very involved and require training and learning to master. I guess you could make the case that Solidworks seems to have a better social media presence with training videos on Youtube, etc. I personally have never found a training series on YouTube that was as effective as an online curriculum or an in-person training class.

I recommend Udemy or Lynda for basic training and more advanced training.

For Example…

To go through the basics of what these CAD/CAM titans are doing these days, let’s take an example of something that needs to be developed from scratch. Let’s use a set of Bluetooth headphones, for example. Some of the parts include:

-Plastic forms that fit together to make the actual headphones

-Soft padding that goes around your ears

-Electronic circuitry to process the information

-Buttons on the headphones to control volume or turn them off and on

-Little pieces that click and adjust to fit your head

-The speakers

-And miscellaneous other parts

If you want to model this entire device in Solidworks or Inventor, you need to know precisely how they fit into one another, so you’ll need some plans and measurements. You can plan it out on scraps of napkins (always a classic), or you can draw them up in a 2D CAD program like AutoCAD.

There’s the aesthetic design, usually done by a fruit loop artist. Then there’s the practical scientific design, which is going to be done by an egghead engineer. Of course, you may be smart and intelligent enough to play both roles. If so, good on ya!

After you have a decent enough plan in place, you can open your app and start modeling each individual piece. Apply materials to the parts and color them, if you like, for added effect. Next, open up your assembly and fit the pieces together.

This is an excellent opportunity to look at what you’ve designed, and consider what kinds of stresses it might be put under. How resistant is this material to twisting, being sat on, or chucked in the back seat of your car after a workout? All these things can be tested with the simulation tools in Solidworks or Inventor.

After running some simulations, you realize that the material you’ve selected for the casing isn’t strong enough. So you can start researching different types of plastic to make it more durable. When you find the perfect plastic, you program the material’s qualities into Solidworks or Inventor so you can apply the new material to your 3D model.

Now you can take the latest 3D model to the right manufacturer, and they can produce your parts using the data in your model. When you get all your pieces together, you’ve got your first prototype. Just put it all together and program the electronics (yeah, like that’s easy to do…), and you’ve got yourself a set of Bluetooth headphones from scratch. It isn’t easy, but it’s actually do-able these days.

Summary

So overall, I’m sticking with my original verdict. Inventor and Solidworks are comparable to one another, so I can’t say one is better than the other. In the end, it will just be a matter of your personal preference. If there’s an advantage that I can say one has over the other, it would be Inventor. Inventor, even after 12 years, would be less expensive than Solidworks Premium.

It is compatible with all the other apps that Autodesk offers, which might be useful in the professional arena with all the other Autodesk programs running around. If you’re serious about developing products or CAD/CAM software, try BOTH of these apps to see which makes more sense to you. The 30-day trials are ready for download.

Chris Graham is an experienced Computer-Aided Design (CAD) draftsman and a writer. He has extensive knowledge of almost all the top CAD software available on the market these days. From simple tasks to developing a professional CAD drawing, he can do everything.

He also has a Bachelor of Architecture (B.Arch.) (Landscape Architecture & Civil Engineering) degree from the Louisiana State University School of Architecture and Design. He has worked at the Corporate Green Landscape Management where his duties included landscape design, irrigation design, landscape installation, CAD drafting.

Compatibilities… Why doe we need Inventor export to Revit (or any other BIM-CAD-software)? Well, easy answer by example: If you design, let’s say, a ventilation unit and all it’s accessories for a building, you definitly have the needs to export all of this into Revit for your BIM-model. Not only as dumb lines, but as a series of intelligent objects, connecting with all aspects of the building. You even may want to use Generative Design with these parts to develope your design or expand on collision warnings, etc. THIS is exactly WHY there is a huge demand for exporting CAD/CAM data out of Inventor into Revit.